M-BACN-12 rolling through East Wye Switch Upper Huron (EWS UPPE)

CASS RIVER SCENE

My February post touched on the ground work that was going into creating the Cass River scene on my upper level. Over the past few week I have been making terrific progress with not only scenery but the actual through truss bridge that spans the river. Lets look closer at the work completed and whats up next to finish the scene.

The previous post showed the contour work and base layer of latex paint to kill the blue / pink foam tone. Next comes a layer of true Michigan dirt that I bake and sift to get the right consistency. Having family in Michigan the odd request comes around once a year.... "Yea so can you send me a box of dirt".... They always deliver. I first put down full strength white glue with a paint brush and then using a spoon add the dirt. Giving it 10 to 15 minutes I then come back with a vacuum to remove the excess leaving a nice dirt layer.

Getting ready to bake the dirt in a aluminum pan - 350 degrees for 30 minutes

Dirt layer in place, needing to come back with the vacuum

- Greenage

After adding the dirt comes a mixture of foams, flocks, and rocks to give the area life. I use some photo for reference but remembering things in nature, just attempt to go with what looks right. Following the tried and true method, wet with isopropyl alcohol and then soak in scenic cement. I have tried a homemade blend of cement, I love Woodland Scenics preblended stuff the best. Can get it a Hobby Lobby with a 40% coupon for around $6.

On the river and banks will be a sand mixture mixed with small river rock to blend in.

Layering the scenery really does bring this area to life

- Next Steps

With primary scenery in place and secured I will now be completing the riverbed scene with rocks and sand. Once dry and cured the process to pour Magic Water will take place and finish getting the river complete. I expect to do this at the end of March, so I will be sure to show step by step how that process works and the great results it produces. Prior to pouring the water, the bridge and ballast work will be completed. Wrapping up this area will be alot of Scenic Express Super Trees.... alot..... UPPER HURON SCENE

Since I have all of the materials out it only makes sense to keep with the momentum and scenic another adjacent scene to the Cass River which is the Upper Huron scene.

About the scene: Upper Huron is not a fictional tower on the railroad but also a neat operation element as well. Upper Huron or UH as its know is the location of a operation wye that allows trains to traverse from either direction on the St. Clair Sub onto the Port Belle Sub. The Port Belle Sub is represented by staging however this line hosts the switch to enter the Michigan Sugar plant and sees a daily local turn during the session and occasionally a unit rock train from a quarry. The actual scene depicted hosts a grade crossing leading into town modeled by a Sceniking backdrop, the sugar beet plant, and a modern water tower in the middle of the wye. Anyone familiar with Michigan knows about all of the unique water towers, UH will be no different.

Out of flat blue foam, comes terrain shape via pink foam and sculptamold

View east looking at the sugar beet plant, and east wye switch. You can see where the scenery currently stops.

Water tower right in the middle of the wye will have character of its own. AEI reader site as well in Upper Huron.

Still alot of work to do in this area but wow just getting some terrain shape, paint, and dirt down really helps make the area more appealing.

RAILCAR FLEET ADDITION - GUNDERSON 5188

Earlier this month Michigan Interstate received the first of a larger covered hopper being added to the agriculture fleet. The 5188 cubic hopper is slightly larger than our most modern being the Trinity 5161 cubic and the two will be mixed in together to provide our customers newer high capacity cars to get their grains to market. In preparation for this add the fleet did cascade seeing the venerable ACF 4600 cubic cars retire and find new life on the Delmarva Central out east.

Fleet Plan (Effective March 2018)

4600 cubic - retired from fleet

4650 cubic - owned by Mich. Ag. Commodities for single or quad-block

4700 cubic - sugar beet pulp, sugar beet pellet, agricultural single

4750 cubic - agricultural single, agricultural quad-block

5161 cubic - agricultural single, quad-block, and unit

5188 cubic - agricultural unit

A quad block on their way to their first loading at M.A.C.

Of course in the process of purchasing the cars, MCIS decided to go with the Scaletrains Operator version since lets be honest the details are good enough and I am rough on the equipment. In short order I had the variety pack of FRA 224 reflectors from Smoke Box Graphics and our mechanical forces proceeded to get them compliant.... Not sure how they got from Sahagun, Mexico to Michigan without reflectors....

Great job by Scaletrains and Smokebox Graphics for great new innovative products, they hit these right on the mark!

Looking pretty sharp - MCIS 5827

CASS RIVER BRIDGE

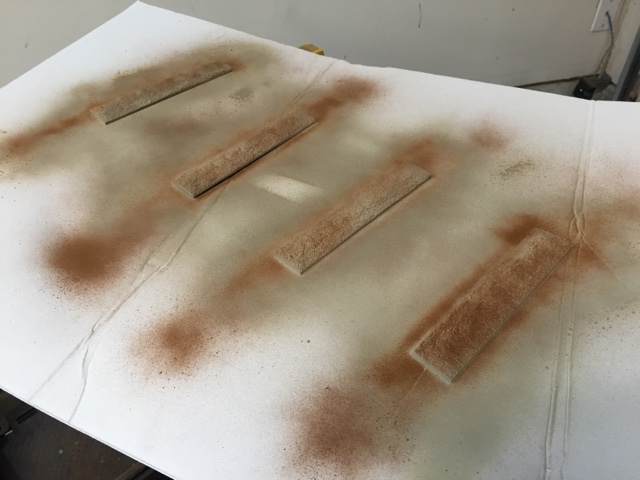

Following Tom Patterson's step by step from MRH I used gouache paints to weather my through truss bridge. I dont want to take anything away from the article so recommend if you are interested in doing this, take a look at the November 2011 issue and go from there. All of the paints can be purchased at a craft store and one thing I did discuss with Tom is using distilled water over Microsol is just as good and even better. I ended up doing the first overall wash with Microsol, but the random sponge work was done using water. Enjoy the photos.

After a few days - proceeded with the random burnt umber and burnt sienna wash

Bridge complete and dry - wow the washes really made it pop

Closeup of the girder and rivet plates - Michigan elements have taken its toll

Simple technique - amazing results.

OREGON JOINT LINE - MARCH DOUBLEHEADER

Wrapping up this post, we are going to have to get slightly smaller... like n scale small and head on over to Dean Ferris' Oregon Joint Line. Recently I had the opportunity to participate in a double header operations session. For the morning session I was the dispatcher and had a good time pushing around fifteen trains across the railroad in preparation for the afternoon shift. Following a lunch break by the pool I crossed over and went into management as the Assistant Superintendent. This role is to help the layout owner (Superintendent) with getting operators orientated and running. Lets be honest from the management side the railroads operating on the OJL are not making any money with idle trains. If you can tell there was some management adversity built into this session all to have a little fun. Right off the bat I was handed a wire describing the need to run a rotary plow extra account snowfall at Snowline!

I blew up the photo real big so you can see, there is definitely some friction between the unions and management. Believe the operator may have added more letters to my last name then I thought were there. None the less the railroad cannot operate effectively if the summit grade of the line at Snowline is blocked. Myself and engineer M. Thidemann didn't know what we would find until we got up on the summit and "Oh $#!% thats alot of quicker picker upper snow". After a few runs at it we cleared the siding and ran down to Kinzua to turn the extra on the wye and go back at it from the other direction. Upon returning to the summit at Snowline we found the mainline now blocked due to shifted drifts and snow with almost a paper like consistency.

Making a run at the drift in the siding at Snowline.. Took us three runs to clear

In the end it was about keeping them moving like we see here with a meet at Fossil.

Having a morning and afternoon session where everyone from both sessions could get together and have lunch was a great idea. So many times having a session limits you to a certain amount of folks not allowing any networking outside of the session, but in this case folks were able to talk shop, eat, and either wrap up or start their operating day on the OJL. Great job to Dean for planning this and having me help with both sessions.

That in a nutshell is my March update, still have another two weeks left of the month and plan to keep making good progress on the Cass River and Upper Huron scenes so stayed tuned and safe travels to all out on spring break.

GM